R&D / Manufacturing

PROGi R&D staffs think outside of the box in traditional suspension and chassis parts supplies.

We invent products that with high-cost value and differences from existing products in the market.

To keep us creative, PROGi joint industry-university cooperative research project in auto parts for the up-to-days ideas.

More importantly, we aim to manufacture products that can be highly applied and satisfied by the majority. Great ideas can be use in reality.

Main development engineers

Our professional product development engineers collect and analysis development data and come up with more design ideas.

After the product is produced, they involve themselves in the practical experiment to solve any impractical problems and improve production procedures.

PROGi is recruiting related engineers for the global changing in the auto industry especially to electronic, intellectualized and light-weight products in auto electronics and electric vehicles.

R&D, measurement

2.5D Image measuring machine

Using the machine to measure the relative position and angle of the products, this can ensure product quality before delivery. Therefore, there will be no poor assembly.

PU material test and experimental development equipment

To ensure product safety and the PU material is environment-friendly by its formula and portion, It is tested with hydrolysis resistance, heat resistance, abrasion resistance and oil resistance before launching to the market.

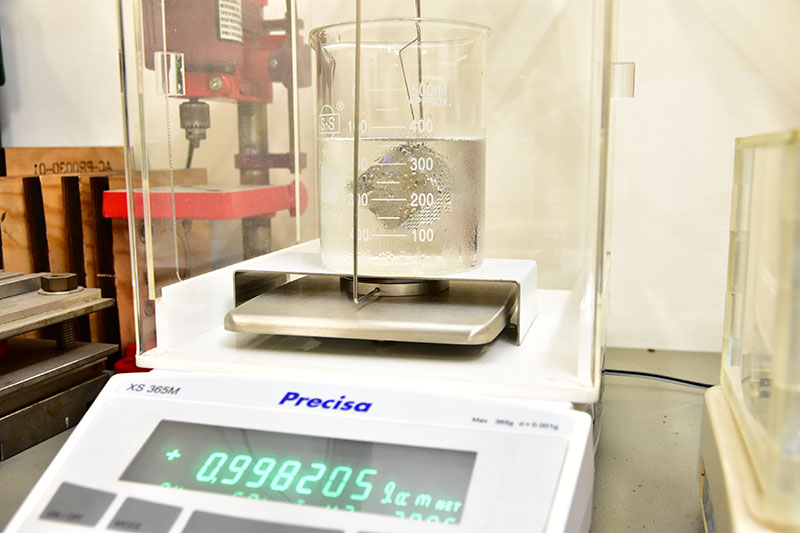

Japanese Rubber Density Tester

In massive production, we carefully control material proportion, in order to produce satisfied and consistency product quality in density, hardness, tensile strength, extensibility and abrasive resistance and many aspects.

Japanese Height Gauge

High Gauge is used to accurately measure product size during production; it is also used at the last stage of quality inspection, to avoid any assembling mistake.

Japanese rubber hardness tester

Rubber hardness tester can measure product hardness and strength precisely. In place of the traditional testing method, it ensures the supplied products fits market demands before leaving our factory.

Rubber tensile tester and Specimen punching Machine

PROGi uses rubber tensile tester and Specimen Punching Machine to randomly check flexibility and hardness of our polyurethane products.

It records the tensile strength, tearing, stripping, compressive, shearing resistance, three point bending and other testing features.

PROGi makes sure our clients only receive products that are safe to use and great quality.

Lathe

Automatic lathe

Automatic lathe likes others can PROGily to large quantity orders and remain high quality of work in each metal pieces. It is our final goal to achieve a fully automatic process for all PROGi orders.

Traditional lathe

PROGi aim to the global but we never forget about minor orders. For newly development models cases and customized requests, we offer manual lathe production to satisfy our clients.

PROGi target us to serve all our clients with high-quality products.

Milling

Milling machine equipment

Milling equipment is one of the main properties to help us reduce the cost of product and labors; it controls time of production to maintain a fast delivery to our clients.

PROGi machines achieve environmental friendly standard in sewage discharge system to support environmental awareness.

Milling machine cutter

You can't make bricks without straw. We have selections of fine quality tools to manufacture our goods. Using the right tools can increase the accuracy and reduce tolerance in product assembling.

Milling machine operation

For higher accuracy manufacture procedure. Milling procedure is necessary after lathing. Therefore, PROGi can always offer the high-quality product and avoid any possible occupational injury.

Other equipment and processing

Plastic intensive mixer

Mixed polymer compound by an intensive mixer, and it is ready for the further process.

Plastic injection machine

A plastic injection can be divided into hydraulic cylinder, crank type, compound type by mold parting, therefore, labor cost can be reduced and maintain consistency of product quality.

Professional photo studio area

Now, comes to understanding, PROGi sees product quality as the key elements. A great description can help clients to choose PROGi products. Whether it is product packing or the print Ads and video Ads; we see it from your side and seek the perfect persuasion to understand our product and the advantages of using PROGi products.